Introduction

The vibrant capital of Tamil Nadu, Chennai, is always changing, necessitating a strong and well-kept road system. This essential infrastructure depends on a sophisticated network of expert personnel, cutting-edge technologies, and tools and equipment for road building. This piece explores this field, looking at:

Roadwork Equipment Situation in Chennai:

For building roads, the city is home to several well-known suppliers and manufacturers. Among the notable participants are:

- Concrete mixers, excavators, asphalt pavers, motor graders, and other road construction tools are all available from the top engineering and construction company Larsen & Toubro (L&T).

- Road construction equipment such as rollers, loaders, and excavators is produced by Sany Heavy Industry India, a multinational firm specializing in heavy gear.

- Asphalt batching plants, pavers, and milling equipment are the products of the local manufacturer Royal Industries.

- Manufacturer of premium construction equipment, including motor graders, soil stabilizers, and vibratory compactors, is Geo Emmanuel Engineering.

Case Studies: Roads in Chennai

Success Stories Many notable road construction projects in Chennai showcase the creative thinking and effective use of machinery:

- Chennai Bypass Road (NH 45): For earthwork, grading, paving, and compaction, a fleet of excavators, motor graders, pavers, and rollers was used in this project. The timely and cost-effective completion was guaranteed by the effective use of technology and equipment.

- Chennai Metro Rail: For station building, track laying, and infrastructure development, this massive mass transportation project used cranes, specialized tunneling equipment, and heavy gear. The project demonstrated how crucial it is to use the appropriate tools for intricate urban buildings.

- Elevated Corridor on OMR (ECR): Specialized cranes and erection equipment were needed for this project, which used precast segmental construction techniques. This creative strategy sped up construction while minimizing traffic interruption.

Future Trends: Creating Tomorrow’s Roads:

Technological developments in the road-building sector are having an impact on equipment development.

- Automation and robotics: Enhanced automation is anticipated to boost accuracy, safety, and efficiency in the operation of equipment. Repetitive jobs like milling and paving may be handled by robots, freeing up operators to make crucial decisions.

- The integration of sensors and networked equipment to gather and analyze data in real-time can enhance project management, forecast maintenance requirements, and streamline workflow. This is known as digitalization and data analytics.

- Energy-efficient options with electric or hybrid drivetrains are becoming more popular in the construction industry since they help cut down on pollutants and emissions.

Eco-Friendly Decisions for a Better Future

The choice and use of equipment are essential to reducing the negative effects of road construction on the environment. Here are some crucial things to remember:

- Selecting fuel-efficient equipment: Choosing equipment with reduced emissions and fuel consumption is a big step toward sustainability.

- Appropriate equipment upkeep: Consistent upkeep guarantees peak efficiency and reduces emissions and fuel usage.

- Using reuse and recycling strategies: Reusing resources like concrete and asphalt lessens the environmental impact and need for new materials.

- Examining sustainable: substitutes for conventional building materials, such as locally sourced resources and recycled materials, can help mitigate environmental effects.

Effect on the Development of Equipment:

The evolution of equipment used in road construction is already being impacted by these trends. The following are the investments made by manufacturers:

- Electric machinery: hybrid reduces emissions and noise pollution.

- Equipment that is connected: Allows for remote diagnostics and monitoring for better upkeep.

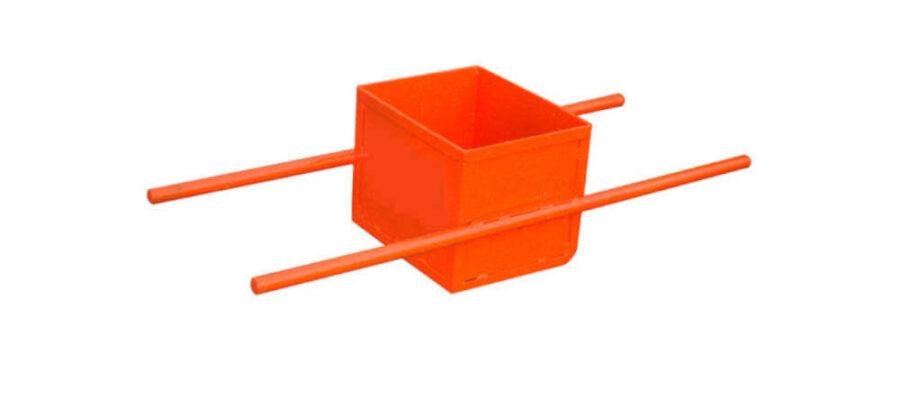

- Equipment that is adjustable and modular: Provides more customization and flexibility for projects.

Sustainability: Constructing Roads with Conscience

Reducing the negative effects on the environment from road construction requires careful equipment selection and operation. Here are some crucial things to remember:

- Fuel efficiency: Choosing fuel-efficient machinery and adopting eco-friendly driving techniques.

- Reducing noise: Making use of quieter machinery and reducing construction activity at night.

- Material sourcing: Whenever feasible, choose locally produced aggregates and recycled materials.

- Waste management: Reducing landfill waste by putting appropriate waste management procedures in place.

In summary

The road-building sector in Chennai is a thriving ecosystem propelled by sustainability and innovation. The city will require effective and responsible road construction techniques as it grows. Chennai can guarantee that its roads continue to be smooth, safe, and environmentally responsible for future generations by utilizing the newest equipment, technology, and sustainable practices.

Post a Comment

You must be logged in to post a comment.